|

WARPING is one of the home craftsman's biggest headaches. After spending considerable time, money and

painstaking care in producing a fine piece of furniture, it is disheartening and a keen disappointment to

have it later warp and shrink and come apart. But shrinkage and warpage can be held to a minimum by proper

conditioning of the wood and by maintaining a close check of its moisture content at the time it is fabricated.

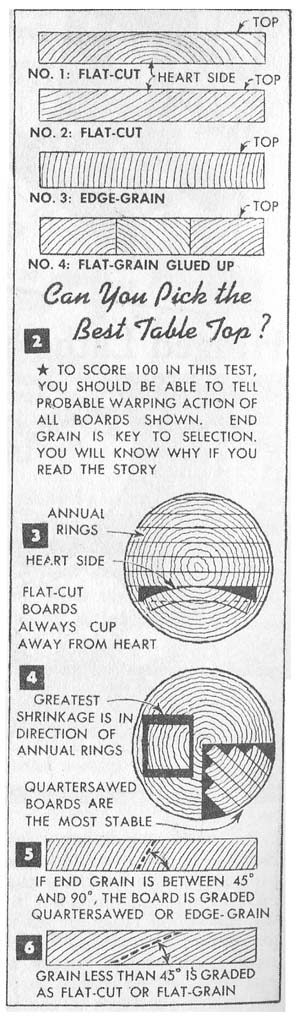

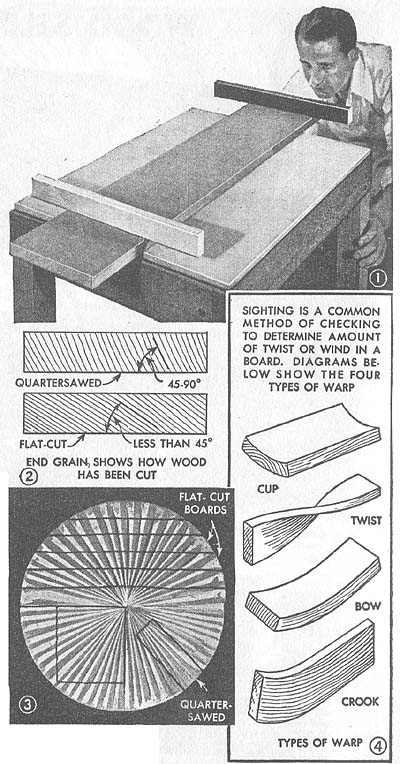

How wood warps: Wood shrinks and warps in definite relation to the direction of the annual rings,

and shrinkage is about twice as great when the direction is parallel with the rings as when it is across them.

This basic principle is illustrated in Fig. 4. Quartersawed (edge-grain) lumber shrinks the least because

the heaviest shrinkage takes place across the narrow dimension of the board. Flat-cut boards have the

greatest shrinkage across their wide dimension where it is more noticeable. Also note, Fig. 3, that

flat-cut boards tend to cup away from the heart side. This is an important point and should be remembered

in joinery.

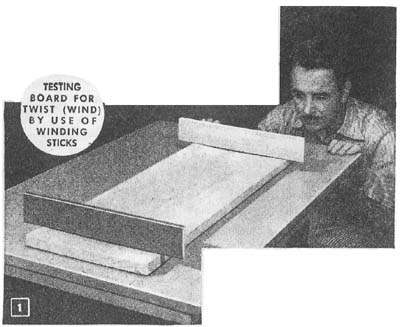

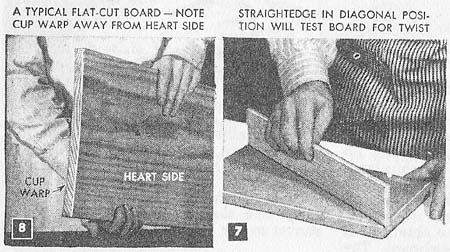

Detecting warp: Any irregularity caused by warp should be removed because a board that is warped even

slightly will continue to twist no matter how it is used. Cut warp, Fig. 8, is detected with a straightedge

placed across the board, whereas twist or wind is determined with a pair of winding sticks, Fig. 1, or by

placing a straightedge from corner to corner, as shown in Fig. 7. Both methods will reveal two high corners

if twist is present, and consequently planing should be done diagonally from high corner to high corner.

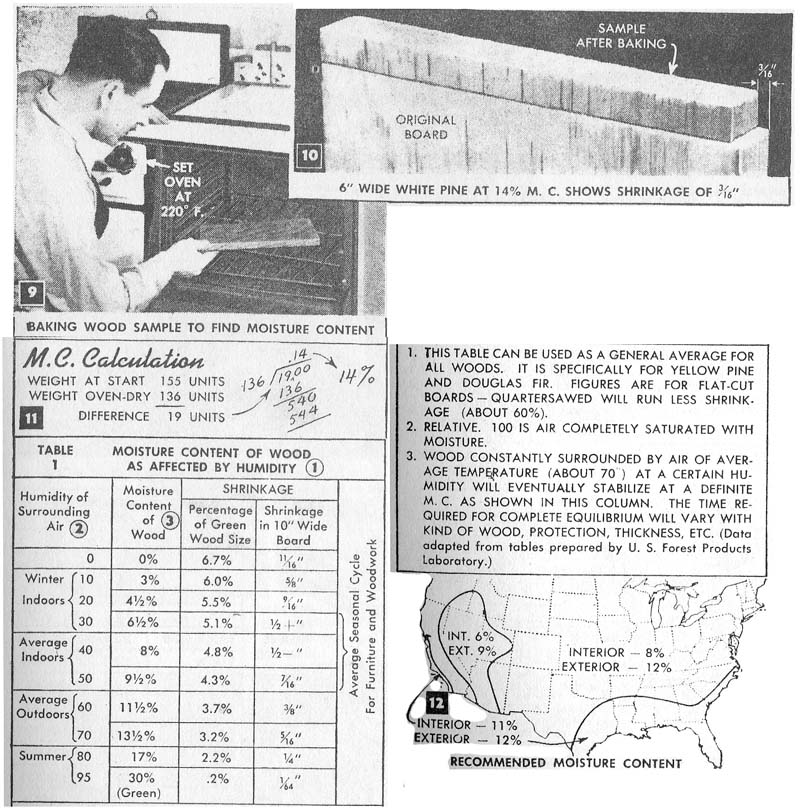

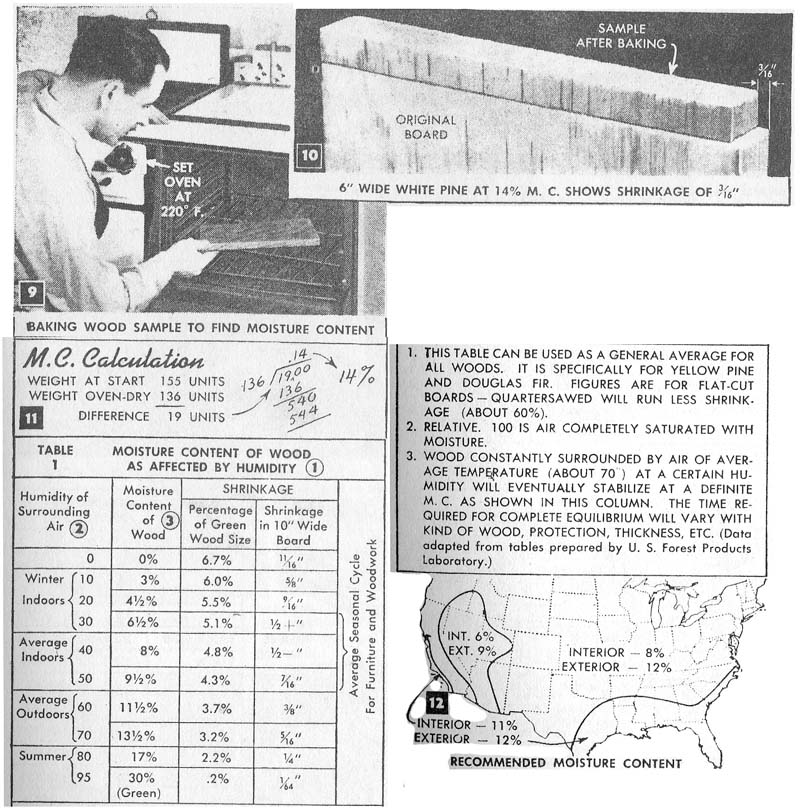

Conditioning: conditioning means seasoning the wood to the proper moisture content (M.C.) to correspond

with the humidity of its permanent location. The map, Fig. 12, shows proper M.C. for various sections of the

country, based on year-round humidity. A variation of 3 percent either way is permissible. Suppose,

for example, that you live in a state where the humidity is about 40 percent indoors all year round.

Table 1, Fig. 11, shows that the moisture content for furniture under such conditions should be 8 percent.

If the wood is 8 percent M.C. to start with, it will be stable and will shrink and expand little even during

the cyle of seasonal changes.

Determining M.C.: It is interesting and instructive to make a moisture-content test. Cut a strip about

1/2 in. wide from the center or about 1 ft. from the end of your lumber. Weigh the sample carefully, using

a small scale reading grams or grains. Place the sample of wood in the kitchen-stove oven set at 220 deg. F. and

weigh it every 20 minutes until it stops losing weight. This will take about 1 1/2 hrs. Then, work out

the calculation given in Fig. 11, and you will have the M.C. The amount of shrinkage of a test sample is

graphically illustrated in Fig. 10. Although the sample is now bone dry, it won't stay that way.

Within three or four hours it will regain approximately half of its lost moisture and size, and in a few

weeks will be nearly normal. This verifies the fact that wood is never truly seasoned -- lumber 100 years old

will absorb 16 to 18 percent moisture if stored outdoors. The best place to store your wood is in a location

where the humidity is about the same as where the finished product will be used. Storing for

several weeks in a warm, dry location is a good conditioning treatment.

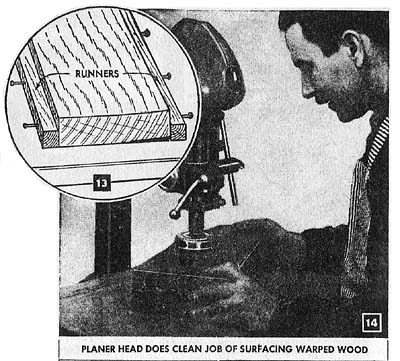

Surfacing: Warped wood must be surfaced. This job is done on the jointer if the stock is within

jointer capacity; otherwise with a planar head, Fig. 14. If the piece is badly twisted, guide runners should

be nailed to the edges, Fig. 13, to form a flat base for the work. In using a planar head, be

sure to adjust it to take a light cut.

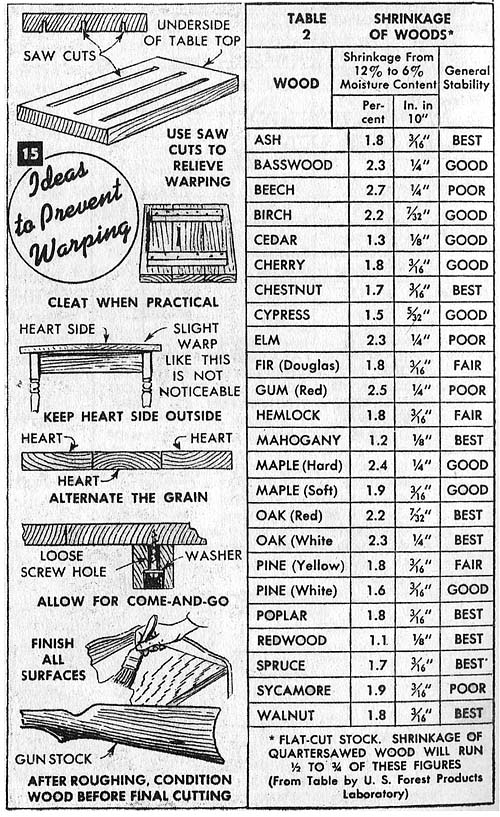

Play it safe: If you have a choice, use edge-grain instead of flat-cut lumber. At least,

avoid extreme grain angles in flat-cut stock. Use a wood known to have low shrinkage and good stability.

Table No. 2. Woods marked "poor stability" often are suitable if properly conditioned. Be sure

your wood is 8 percent M.C. You will note in Table 1 that if wood is 8 percent M.C., the initial shrinkage

of a 10-in. board from green wood will be 1/2 in. scant. The board also will be subjected to a seasonal

cycle of about 1/16 additional shrinkage and the same amount for expansion. However, you will note that

near the end of a humid summer, doors and drawers will swell and bind, and that in the dry indoor air of

winter they return to their original M.C. and work smoothly. Some of this normal shrinking and expansion

can be stabilized by reinforcing and solidly anchoring the wood in assembly. Thus, if humidity is not

excessive, the wood will compress within itself and follow the path of least resistance. However, if you

fabricate wood having a 16-percent M.C., the stain of stabilization at 8 percent is just too much, and

"pop" go your glue joints and fastenings.

Retarded warping: The end grain of stock roughly cut into turning squares and stored for future

use should be given a protective coating of shellac, varnish or oil paint to prevent checking.

Lumber salvaged from old furniture and resurfaced on one side only is more apt to warp than if surfaced on

both sides, as freshly dressed surfaces invite rapid absorption of moisture. Furniture should be finished as

soon as possible after it is completed. Linseed oil, shellac, varnish and other finishes, when applied to

the surface of the wood, form a practically airtight covering through which moisture penetrates slowly.

Finishing coats retard swelling and shrinkage to the point that if the humidity increases 10 percent for a couple

of days, there will be no appreciable change. If your wood is conditioned to 8 percent M.C., it will remain fairly

close to 8 percent and you will not be troubled with warping. Ideas in Fig. 15 are worth noting in preventing

warping and shrinking. Notice how cupping of a table top is avoided.

|

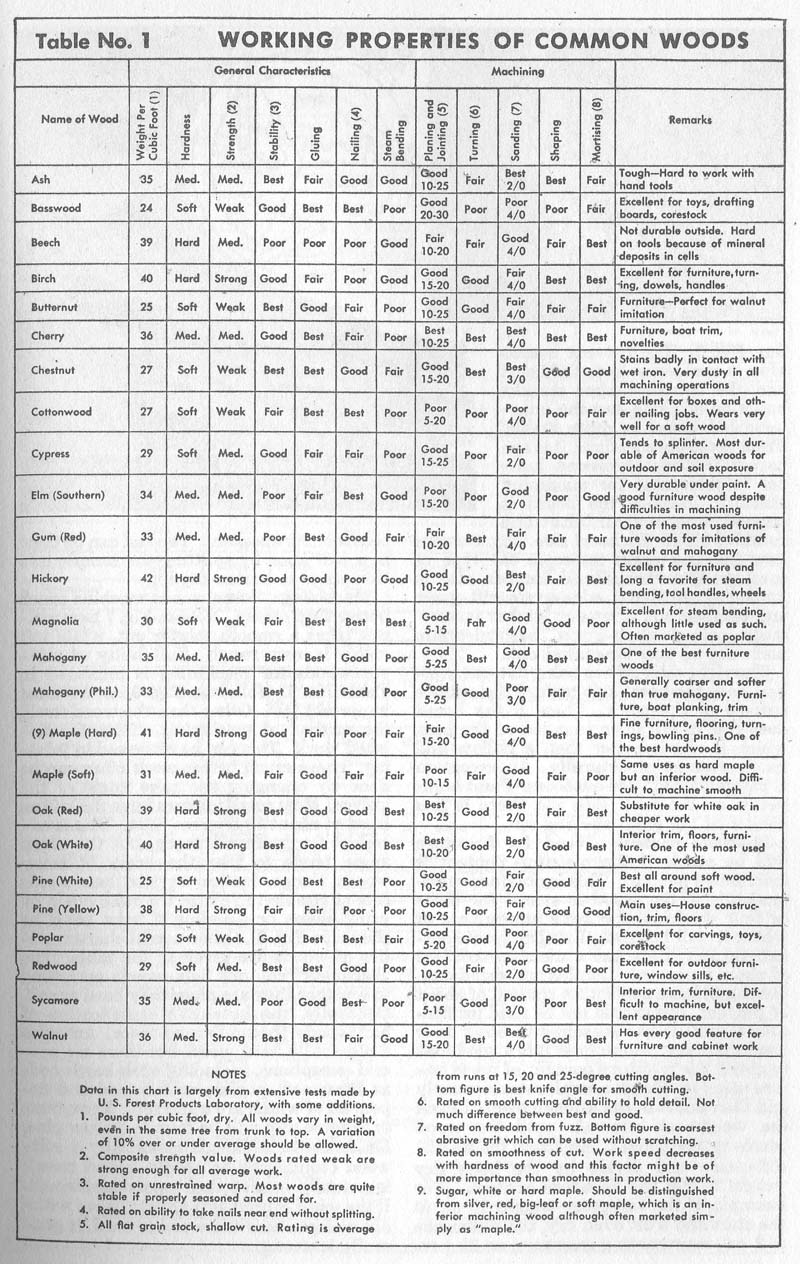

KNOWING wood not only adds to the enjoyment of crafting but also helps in making any project a success.

Naturally, the crafter is chiefly interested in how the wood will look when finished, but other important

features should not be neglected.

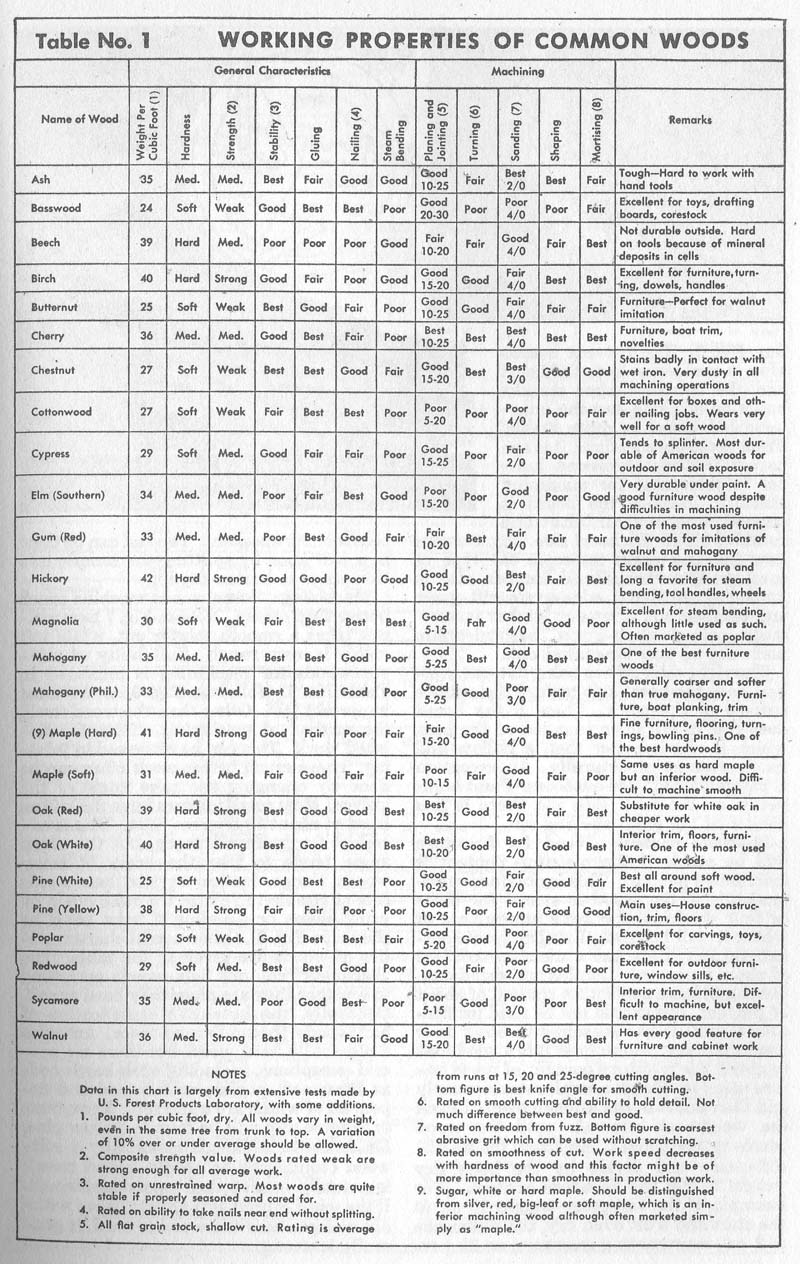

Stability: "Will it stay put?" is an important consideration in all forms of woodcrafting. All woods

shrink in seasoning, which causes distortion or warp, the four principal types being shown in Fig. 4. Some

woods warp more than others, as indicated in Table No. 1, and can be made more stable by proper use.

The common method of testing a board for warp is shown in Fig. 1. Sticks placed at either end of the board

reveal cup and also show any twist or wind. The top edge of one stick should be light and the other dark to

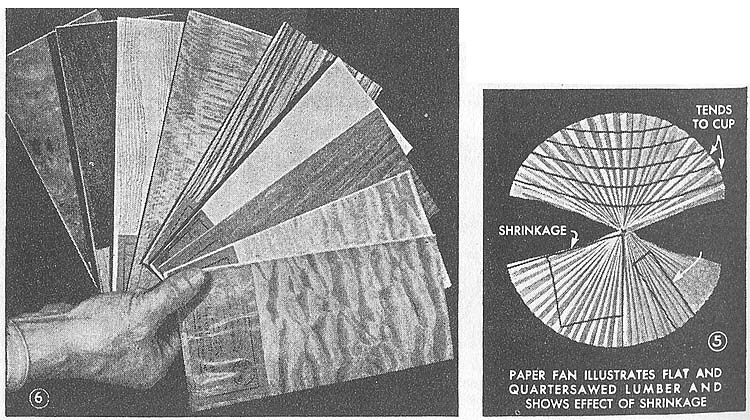

provide maximum vision. Just what makes a board warp is often illustrated by means of a fan made

from a strip of thin paper about 6 in. wide by 2 ft. long. Brush marks are drawn across the fan to

represent boards sawed from a tree, Fig. 3. Shrinkage in wood always occurs along the annual rings,

so that if the fan is cut on either side, it will immediately shrink just like a split log would do. What

happens to the original straight boards is shown by the fan, Fig. 5. The flat-cut boards always

curl away from the heart and the square timber shrinks badly on one side, but the quartersawed board is

quite stable. From these observations, it is certain that the rounded side is the heart side. Fig. 2 shows

how the end grain indicates the type of sawing. Quartersawed lumber also is known as radial-cut, edge-grain,

rift-grain and comb-train. Flat-cut lumber is variously named slash-grain, bastard-grain, plain-sawed and

tangential cut.

The right side: When using flat-cut lumber, keep the heart side toward the outside surface of

the work. Then, if the board does cup, it will show rounded on the face, which is much better than a hollow

and much stronger structurally. An exception is painted wood used outdoors. Paint holds better on the

bark side and there is less danger of the grain shelling out.

Moisture content: Wood for furniture will be stable if the moisture content is from 6 to 8 percent.

This is obtained automatically if the wood is stored for three or four weeks in the same atmosphere at

which it will be used. Lumber from commercial dry kilns has a moisture content of about 8 percent.

Lumber air-dried outdoors will have a moisture content of about 20 percent, and should not be used

for furniture until it has seasoned three or four weeks indoors. Sometimes it is a good idea to check

the moisture content of wood before using it. Weigh a small sample exactly and then put it in the kitchen

oven. Check the weight at intervals until the wood ceases to lose weight. Ascertain the weight difference

and divide by the bone dry weight to get the moisture content (M.C.) For example, if the test piece

weighs 10 oz. at the start and 8 oz. oven dry, the difference is 2 oz., representing moisture, or 25 percent

moisture content. The test can be done in a half hour by splitting the sample into thin strips to hasten

drying.

|

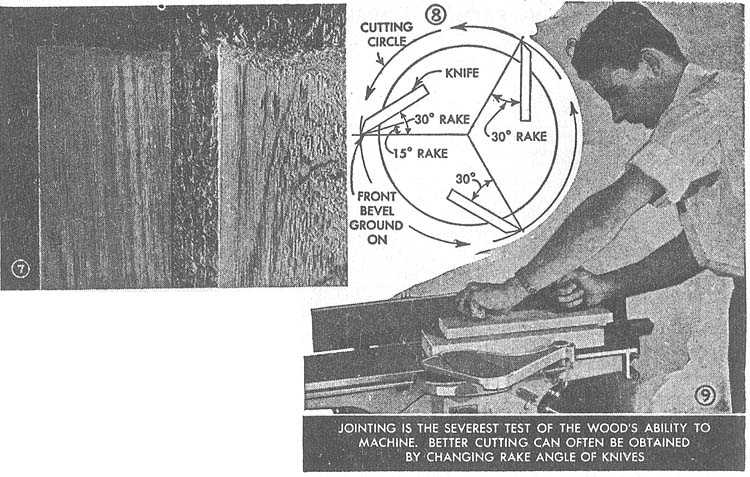

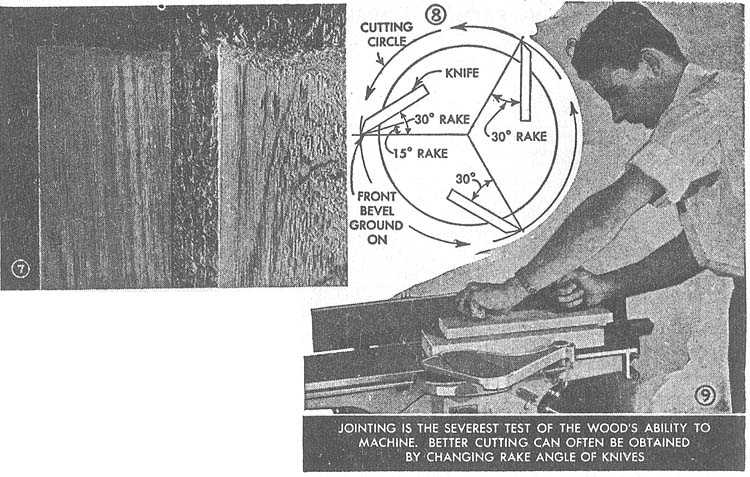

Machining: Some woods machine much better than others. Note in Fig. 7 how walnut takes a

smooth jointer cut, while soft maple is very rough. Suitability of various woods for machining is indicated in

Table No. 1. Jointing, Fig. 9, is the most important test. Other than the wood itself, the method of

machining affects the finished work. This can be observed in jointing, where much better work often can be

done by changing the rake angle of the knives. Most small jointers have the knives fixed at about 30 degrees

rake. This is excellent for knife efficiency, but the sharp angle tends to tear the grain of many woods.

For production work in these woods it is advisable to reduce the rake angle by using shims or grinding a

front bevel as shown in Fig. 8. Other useful characteristics of wood are given in the table. The

"hardness" column lists woods according to whether they are physically hard or soft. Generally,

the botanist's classification of hardwoods (board-leaved trees) indicates a physically hard wood, but there

are several exceptions, including such hardwoods as basswood, poplar, cottonwood and aspen, all of

which are quite soft. Exceptions in reverse also will be found. Yellow pine, for example, although

botanically a softwood (coniferous or needle-leaved trees), is actually harder than many hardwoods.

If the wood is hard, it is always heavy without exception; if the wood is hard, it generally is strong.

|

LARGER TABLE IMAGE

LARGER TABLE IMAGE

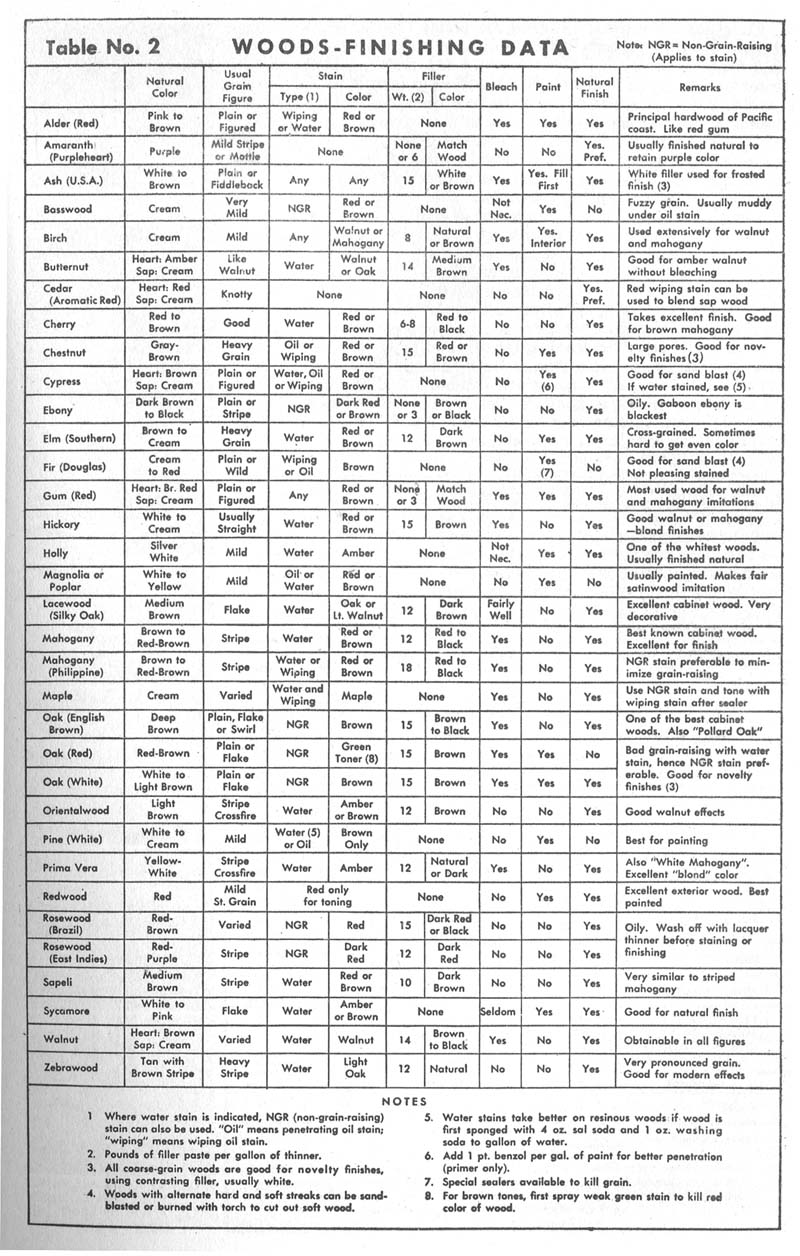

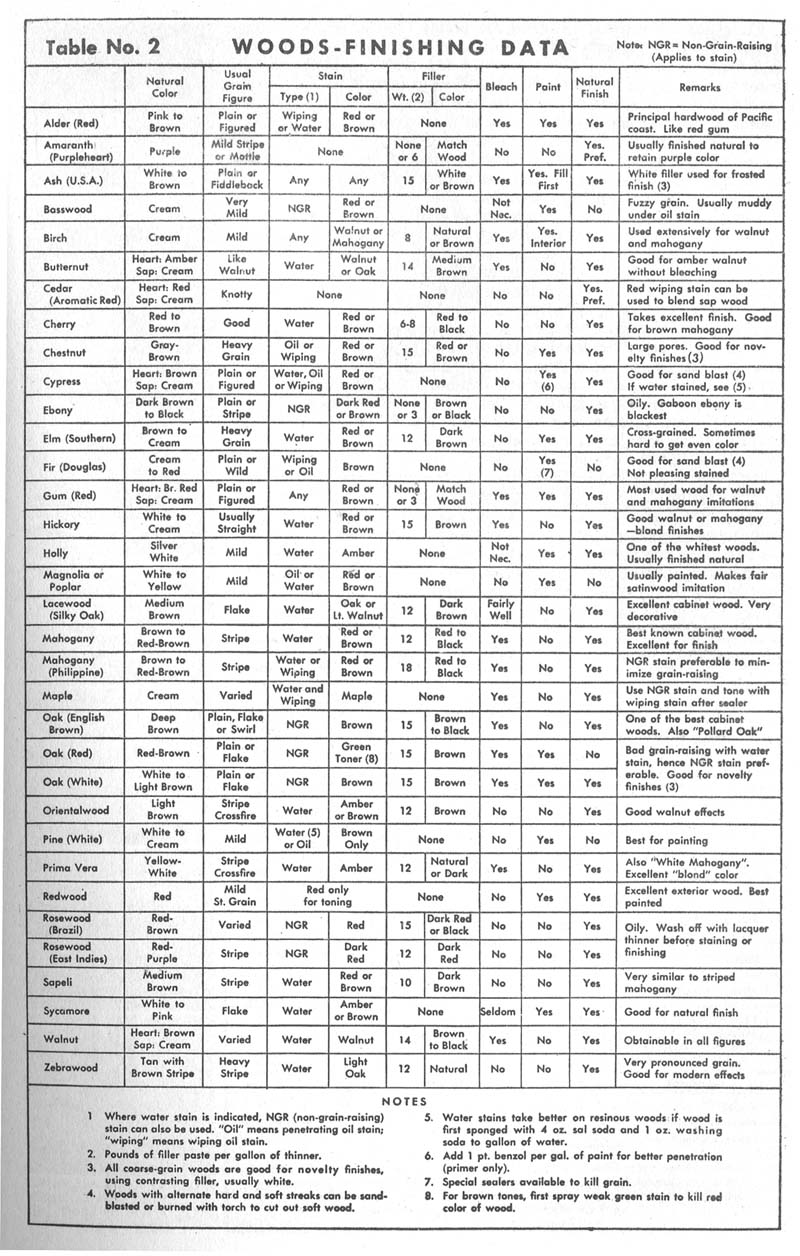

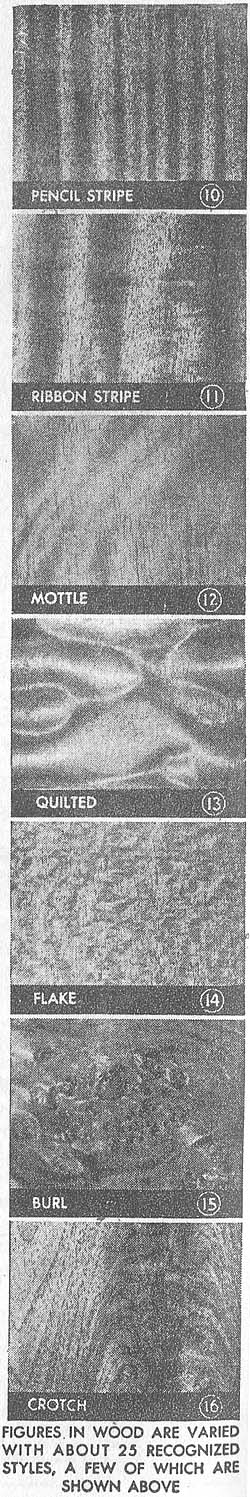

Finishing: Finishing often is the prime characteristic in selecting a cabinet wood. When you have a

wood that machines and finishes nicely, then you have a top-notch cabinet wood. Information given in

Table No. 2 will help in selecting a wood for finish, and is a fair guide as to how the wood should be

finished. Finishing is closely related to the natural beauty of the wood, necessitating some knowledge of

grain and "figures" for suitable selections. Figures in wood constitute a whole subject

in themselves, and the few samples shown in Figs. 10 to 16 can be taken only as typical examples. Perhaps

the best way to become acquainted with figures and also the many different kinds of woods is to purchase

a set of wood samples, Fig. 6. A set of fifty samples is an inexpensive and worthwhile investment, and it

is surprising how quickly identification and general knowledge of various woods can be learned by "leafing"

through such a set. The samples are small wood blocks packed in a neat box and should be kept in a clean,

dry place.

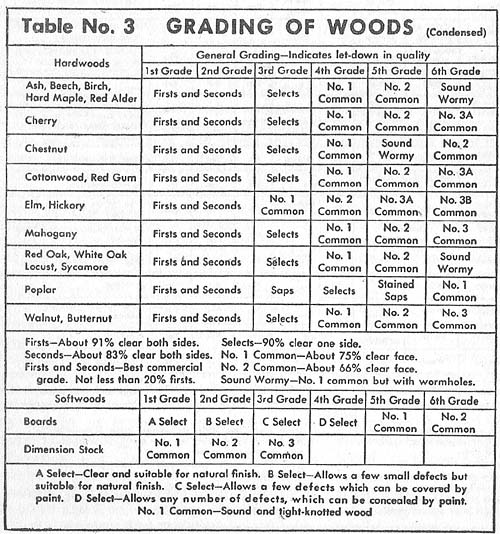

Grading of wood: A knowledge of wood grading is useful. For example, if you want a popular board

for painting, you would order "stained saps," (fifth-grade lumber), and the finished job

would be practically as good as if made from "firsts and seconds." Essential grading data is given in

Table No. 3. This table is not complete nor absolutely accurate, but it can be taken as a general guide.

There are actually ten grades of lumber. Of these, eighth and ninth grade mahogany is the only one of interest

to the crafter. This grade comprises wood of firsta and seconds quality but in short lengths. it should be

noted in the table that numbered gradings are not comparable between different woods. For example,

fifth grade popular is a much better wood for a paint job than fifth grade chestnut. Grading rules for

softwoods are much diffeent than for hardwoods, and the differences should be carefully noted from the table.

|